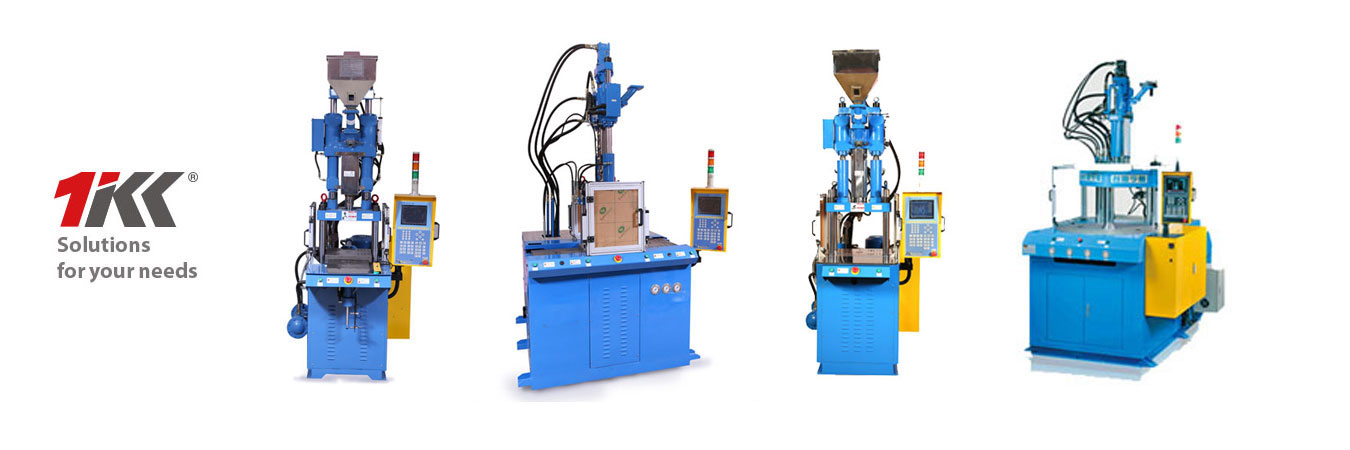

D & M Enterprises

Founded in the year 1999 with a vision to become a most preferred and reliable Supplier of Plastic Injection Moulding Machine in India. We supply Horizontal Injection Moulding Machine, Vertical Injection Moulding Machine, Auxiliary Equipment for Injection Moulding Machine and Automation for Injection Moulding Machine

AMC Services

We Provide Annual Maintenance Contract for both Horizontal and Vertical Injection Moulding machines and Automation Injection Moulding Machine at an economical cost.

Service & Spare Parts Support

We have providing extensive service support and spare parts support for the Horizontal and Vertical injection moulding machines, Auxiliary Equipments for Injection Moulding Machine supplied by us.